A designer’s freedom is achieved when a perfect model is manufactured. The liberty achieved through high gravity compounds which helps any model to restrain the best effect produced by iron and steel. This is an engineer’s gift as this completely replaces any toxic substance from the spaces which the model holds.

A Perfect Substitute

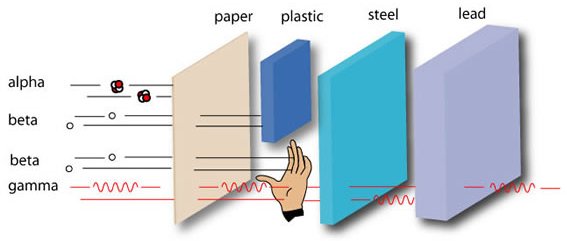

The balancing applications using the high gravity compounds are spell bound. The compounds will help restore the exact weight required for the circumstance. These compounds are a fantastic lead substitute and it is completely eco-friendly.

High Quality Properties

The highly engineered thermoplastics have their properties intact. The incredible amount of support it offers to the system is a boon for any formation. The following are the support that these thermoplastic materials can offer

• High Tensile Strength

• Immaculate Impact Strength

• High Dense Flex Strength and Modulus

• Amazing heat deflection due to rise in temperature

Standardized Proposition

Industry standards are completely met;however, this organization looks up to health standards too. This paved way for them to come up with eco-friendly materials which can substitute any toxic substance. This widely helps in being flexible with ever changing standards. The amazing areas of support to offered right from commercial entities as well as households.

Surprising Prices

The regular concern with any of the end user is the cost factor. The presence of high density polymers and techniques involved to make them involves cost. However, it is a sweet surprise that it not only replaces many other materials, but it comes at a very less expensive price. The eco saving blended with reduced cost makes these thermoplastics the best in use for the future.

The high gravity compounds help in many industries. Say for example the automobile industry. It makes the vehicles less weight. Easily replaceable. The ductile property of thermoplastics helps to get molded to any form. In fact, the small spaces which is very difficult for any substance to fit in, thermoplastics stays strong and flexible.

The applications of the high dense compounds are many. The positive approach by the industries to replace poisonous substance makes an incredible change among the people’s mindset. The melting point of these compounds are very high, and it can withstand high pressure situations.

The Only Solution

The ever-expanding production costs due to usage of many metals is easily avoided. Many products have these troubles. The main concern is the small space fillers which will be highly expensive. This is due to the fact that most of the filler materials comes with huge costs. Not to stop there, molding to fit in the right space is also an expensive process.

The thermoplastics are a wonderful medium to overcome this difficulty. Firstly, the cost is less and the molding process is also easier to fit the space. The compounds are many, the perfect usage of it must be identified. The engineers have to identify the need and replace it accordingly.

The internal cavity fillers and the most intense and complex machines have thermoplastics fit in it. Brings about a sea change in the outlook of industries. Afterall, giving the best to the people is always a firm’s dream. And when it happens at an affordable price, it is worth giving it a try.

0 comments:

Post a Comment