Polymers have been utilized as added substances in bond mortars and cement since the 1920s when characteristic elastic latex was added to street clearing materials. From that point forward there has been impressive advancement of polymer alteration for bond and cement. Polymer adjustment of bond mortar and cement observably enhances application and execution qualities. These property progressions incorporate less demanding dealing with, better completing, higher quality and attachment, and expanded strength.

In real practice the two speculations are probably going to be pertinent relying upon the typer and science of the polymeric fixings and the conditions present amid hydration of the bond. The circumstance is very unpredictable since some low sub-atomic weight synthetic substances that are available in the business high density polymers can likewise impact the response of Portland concrete with water.

It is essential that both concrete hydration and polymer film arrangement continue well to yield a monolthic lattice in which the bond stage and the polymer film development continue well to yield a solid framework in which the bond stage and polymer stage interpenetrate. The bond hdyration process by and large will happen quicker than the polymer film shaping procedure.

The properties of both new and solidified bond are influenced by parameters, for example, polymer type, polymer-to-concrete proportion, and air content and ecological conditions amid the solidifying of the blend. Unrivalled physical properties result contrasted and customary unmodified concrete blends. It is conceivable that the polymer films in bond go about as split plugs for any microcracks that can create under pressure.

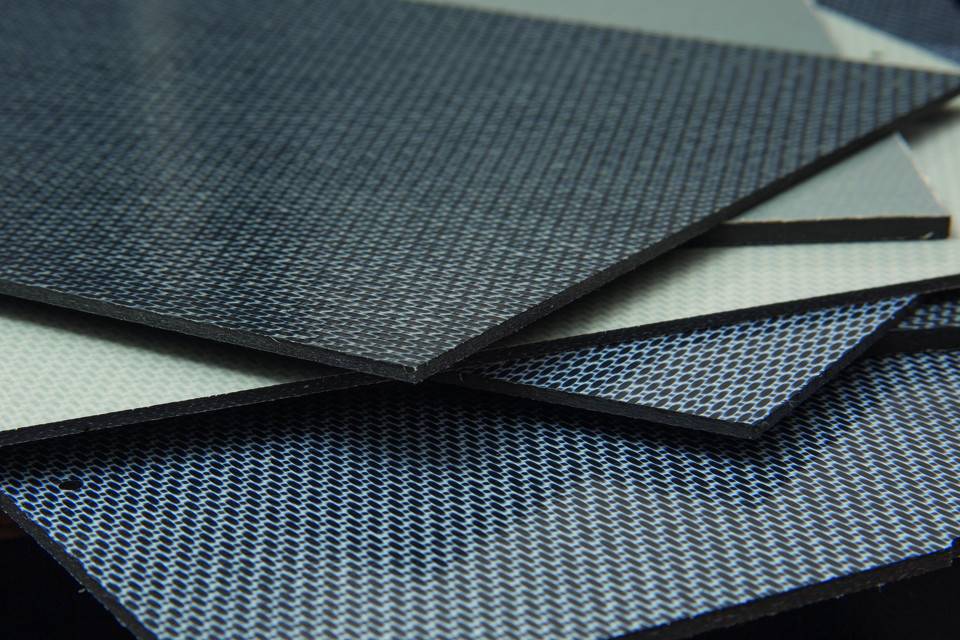

Thermoplastic composite material sheets are the best option in contrast to compressed wood, steel, aluminium, molecule board and so forth. The long sub-atomic structure of Polyethylene makes a hard and strong material enabling the sheets to withstand substantial scraped area and stress while having the adaptability to ingest overwhelming effect and weight. It is a lightweight yet solid and strong material.

Why Choose HDPE

• Environmental Friendly

NEU HDPE Sheets are ecological agreeable item since they are totally recyclable. At the point when the ecological issue is getting more genuine, everybody has the duty in battling Global Warming.

• UV Stabilized

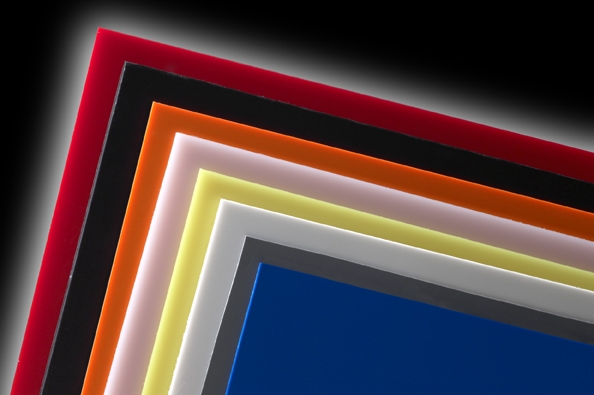

The NEU HDPE Sheets are being delivered for the use of both indoor and open air they are all UV Stabilized ensuring colourfast for no less than 8 years.

• Durability

In contrast to different materials, Lead free ammunition doesn’t decay, fragment, chip, swell, and it is likewise termite safe. It offers any longer life expectancy contrast with different materials.

• Maintenance free and Hassle free

NEU HDPE sheets are shaded sheets where you can pick any shading that you like. You will require no depiction on the off chance that you apply NEU HDPE sheets.

• Cost Saving

Thinking about of the favourable circumstances offered, working with NEU HDPE sheets can help in labour and material cost sparing. It spares upkeep costs in long run as well.

0 comments:

Post a Comment