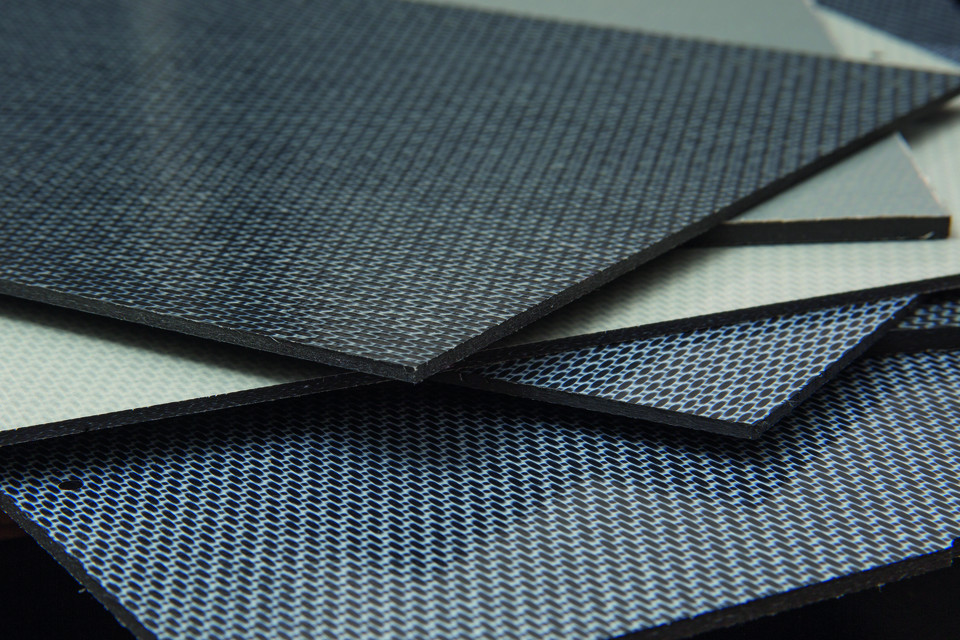

Specializing is the transformation of the most technical plastics by injection molding or compression molding processes. These companies control materials belonging to thermoplastic, thermosetting or thermoplastic elastomer families, whether in the form of granules or natural powders, loaded or not with mineral fillers or fiberglass or carbon, colored on demand.

The high performance plastics have a permanent use temperature of more than 150 ° C and have a high level of thermomechanical properties. In the making of products it works as a lead substitute that is not only cost friendly but also of similar quality.

Thermoplastics and Thermosets: Thermomechanical Performance

Diagram of thermomechanical performances

The properties of plastic parts depend mainly on the performance of the constituent raw materials. The companies place great importance on the choice of the material, which depends on the characteristics sought for a plastic part. In fact, in making things like frangible bullets this is the best deal for you.

There are two main categories:

Thermoplastic Polymers

These are macromolecular materials working as lead substitute whose main characteristic is their possibility of reversible solid / liquid transformation by heat input. Thermoplastics are formed primarily by injection.

Once polymerized by heat, these materials become irreversibly solid. The thermosetting materials are converted by a process called compression or compression transfer.

Thermoplastics and Elastomers

The best company masters thermoplastics and thermoplastic elastomers.

Thermoplastics

Thermoplastics are linear polymers more or less branched, non-crosslinked, rigid at room temperature and, by increasing the temperature, softens and finally become fluid. The reverse process is also feasible. Successive cycles are possible.

Thermoplastic elastomers (TPE)

The finest companies master the small series injection of the main thermoplastic elastomers for medical devices buttons, seals and abutments and mainly uses the following materials, Santoprene, PP / EPDM, colored TPE in relation.

Thermoplastic Raw Materials

Most of the companies use and converts in particular the following thermoplastic raw materials:

• Acrylics and Methacrylics (PMMA

• Polyacetals (POM)

• Polybutadiene (PBT)

• Polycarbonates (PC)

• Polyphenyl Ether (PPE)

• Polyphenyl Sulfide (PPS) such as Ryton or Fortron

• Polyethylene Terephthalate (PET)

• Polyimides, Polyetherimides (PEI)

• Liquid Crystal Polymers (LCP)

• polyphenylenes

• Polysulfone (PSU)

• Polyethersulfone (PES)

• Polyarylsulfone (PAS)

• Polyetherethercetone (PEEK)

The performance of thermosets

Thermosets can continuously withstand high temperatures above 200 ° C or high temperatures for a short time (above 300 ° C), without changing the mechanical strength.

They have unrivaled high voltage insulation or surface current in comparison with thermoplastics. They also have very good flame retardant properties and are hardly flammable. For the Frangible bullets these options are perfect.

Compression molding of thermoset high temperature

Thermosetting Raw Materials

Thermosets are macromolecules that are transformed into various objects under the impact of heat, pressure and chemicals. There is Macromolecules crosslink during cooking. This state is irreversible and thermosets cannot be modified or reused after the crosslinking phase, unlike thermoplastics.

Thermosets are also referred to as crosslinking resins, because for baking the crosslinking agents are essential, for example hardeners, accelerators or catalysts. These are the options now.

0 comments:

Post a Comment