High-density thermoplastic material details are as a rule progressively utilized today in many applications like apparatus segments, radiation protecting and bundling as a result of two fundamental variables which are ecological and wellbeing and security concerns.

It also eliminates the idea of using metals as the high-density thermoplastic can get the work done easily. It is also much cheaper than metal and thus, is the best solution.

The polymer mixes likewise offer structure opportunity and are ordinarily less exorbitant and entangled to process making it the best thermoplastic with many uses in the industry.

High-density thermoplastic proffers significant advantages like feasible, non-harmful details, the capacity to liquefy handled utilizing normal techniques and a superb equalization of properties.

• Advantages of using HDPE

High-density details give significant improvement, to some degree mass yet don't have the downsides of metal like greater expenses, structure limitations.

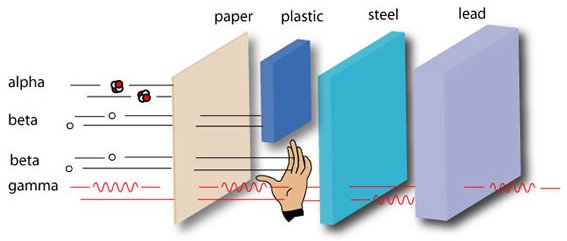

High density plastic is non-lethal, dissimilar to lead metal. It adds to security and manageability activities and offers an equalization of flexural modulus, elasticity and warmth diversion temperature.

The HDPE is available in common objects like jugs, compartments, toys, caps and all sorts of local items. It is one of the most manufactured polymers all over the world for its various profits and advantages. On top of that, it is odorless and non-toxic.

HDPE is adaptable, light, and even function properly in low temperatures and its high protection from the effects.

The high density plastic is not quite the same as the ordinary thickness polyethylene since it has a higher atomic weight, and its manufacturing is very easy.

• Much more dense than LDPE

High density polymersare very different from LDPE in a lot of ways. HDPE has a very high density and all the molecules are tightly packed. Due to this, their density is much higher than LDPE, making it stronger.

Due to such high density, HDPE can be used for heavy-duty tasks and it can even lift a lot of weight easily without breaking.

Therefore, high density polymers are also being used in industries for many heavy-duty tasks. Most polymers melt very easily at a certain temperature. But due to the high density of the HDPE, it can resist more high temperatures very easily without melting.

It is a high melting point as compared to other normal polymers making it the best choice for performing various tasks.

• Benefits of heavy plastics

Heavy plastics has a lot of advantages due to its molecular structure. Some of the best heavy plastics can even stop a bullet from penetrating through it making it the best bullet-resistant plastic available in the market.

Another major advantage of heavy plastic is that it can inhibit flames without any problem. There are many pipes that are being manufactured using these heavy plastics for more durability, strength and low cost.

Due to its strength and resistance capabilities, it is one of the most desired products in the market and is giving tough competition to various metals. The most important factor about HDPE is that it is way cheaper than metals due to which it has such high demand.

0 comments:

Post a Comment