Industrial applications require a lot of properties. The material should be high grade and easy to process. As compared to unmodified grades, thermoplastics are always considered a better choice. The fibers are high modulus types and thus can be used for manufacturing within industrial applications.

• Eco mass graded thermoplastic material is more durable and highly stiff material.

• As compared to unmodified resin type, thermoplastic composite materials can easily be shaped into any possible shape.

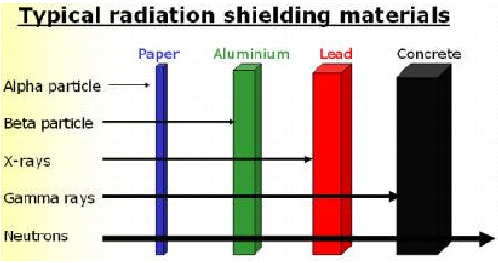

• The material cost is also much compromised as compared to traditional lead or any other metal grade material, used earlier.

Similar process techniques

The processing technique is what makes a big difference in industrial-grade material selection. Just like all other traditional material, the thermoplastic material is also processed in the same way and using the same technology.

This means that for manufacturers to switch to this particular material as raw material, it will not require changing processing technology. Using this material within the manufacturing industry for medical applications or commercial application does not require any specialized upgrading of the processing techniques.

Thus using this material has become the first choice for manufacturers who are looking around for a cheaper yet better replacement for traditional metal.

Improved compatibility

Even when using thermoplastic material for X-ray shielding the material is highly compatible. This means that it can be used in all types of shielding machines in scanners and hospitals. The material is more compatible can be shaped into any possible dimension or shape.

Even when used within industrial applications in scanners, the material is easy to mold into any possible shape and cut. You may not have to consider investing extra money in making new changes in the shielding and scanner machines.

Lightweight

Another major advantage that makes thermoplastic composite materials a better choice for industrial applications is its lightweight. The machine does not have to bear the excess weight of the shielding material. For medical applications, this is one feature that is very beneficial as it reduces overall machine weight.

Due to its lightweight, this material is also highly recommended for wide applications in machine parts, ammunitions and the medical field where durability and strength are needed.

Reinforced features

When speaking of thermoplastic materials, reinforced compounds are practically more in demand due to unique properties. One major feature is that these compounds are available in a wide range of compounds and combinations.

This is one single factor that is also related to the improved performance of thermoplastic for X-ray shielding. They are considered as perfect replacements for traditional lead and other metal materials that are in fact more expensive.

Easily available

When using lead or any other form of metal, the raw material is available only as recycled or ore extracted material. But thermoplastic is not extracted from any type of ore. The material is industrially prepared and so it is easily available in the market.

This is why the material is considered as more cost-effective as compared to extracted or recycled ore. You may not have to worry about arranging raw material in advance as resin fibers can be purchased at any time.

0 comments:

Post a Comment