Last summer, Rawlings launched the Quatro, a new BBCOR baseball bat. A BBCOR bat, or “Batted Ball Coefficient of Restitution,” refers to a regulated standard regarding how much energy is lost during a baseball bat’s contact with the baseball. The higher the number, the higher the bat’s trampoline, or bouncing back, effect. The National Federation of State High School Associations (NFHS) and National Collegiate Athletic Association (NCAA), set 0.50 as the maximum BBCOR value (slightly higher that wood’s trampoline effect).?

The Quatro is an aluminum bat with an inner barrel that’s a blend of carbon fiber and resin. The blend provides a flexible outer shell and a stiff inner barrel. The outer barrel acts as a highly flexible trampoline. A hinge system connects the barrel to the handle, which functions as a vibration dampening collar. The connecting joint, which attaches to the urethane, both ensures that the outer shell never touches the handle and connects to the urethane that dampens vibrations coming off the barrel for enhanced player sensation.

The Quatro demonstrated quick study and anticipated roughly twenty-five percent of Rawlings' BBCOR bat sales

Ecomass Technologies

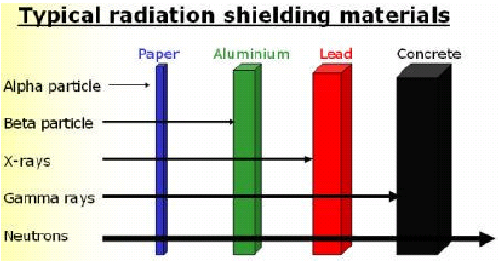

Ecomass Technologies focuses in the creation and production of high density engineered thermoplastics, thermoplastic composite materials, high density plastics, high gravity compounds, and high density polymers. It delivers material solutions to OEMs and material processors worldwide. Its sales representatives and engineers have helped government and commercial customers surpass physical property challenges by developing over 100 high gravity thermoplastic composite materials engineered for weighting, balancing, radiation shielding, and vibration dampening applications.

Ecomass products replace traditional high density materials including lead and other metallic materials. Its high gravity compounds can be formulated up to the density of lead (11.0 g/cc), offer metal’s physical properties and weight, and deliver injection molded plastic’s design and production advantages. Its high gravity compounds can be injection or compression molded. Perhaps soon or even currently, its customers are either offering or will soon be offering secondary operations.

Vibration Dampening

Everything has frequency, either natural or resonance. Natural frequency is the frequency that exists when a system oscillates (or fluctuates) when not subjected to a continuous or repeated external force.

All materials have resonance frequency. Energy waves, which have both frequency and amplitude, cause vibrations. When technicians and engineers can’t isolate and/or reduce energy at the source, they apply dampening materials to lessen, limit, or avoid oscillations and, thus, reduce energy.

All Ecomass Compounds meet the EU RoHS Directive, are 100% lead free, do not contain any U.S. EPA toxic or hazardous materials, and comply with Section 1502 of the Dodd-Frank Act.

Contact Ecomass today or see its website and complete one if its RFQ Forms to find out how you and/or your company might be able to use its compounds for Vibration dampening or apply them to any other valuable use. Better yet, call me.

Ecomass Technologies

Ecomass Technologies’ concentrates on the development and production of high density engineered thermoplastics, delivering material solutions to OEMs, and material processors worldwide. Its sales representatives and engineering have helped commercial and government customers conquer physical property challenges by developing over 100 high gravity thermoplastic composite materials engineered for weighting, balancing, radiation shielding, and vibration dampening applications.

Ecomass’ high density plastics, high density polymers, and high gravity compounds replace traditional high density materials, such as lead and other metallic materials. They offer the design and production benefits of injection molded plastics, while offering lead’s density (11.0 g/cc) and metal’s weight and physical properties. Its high gravity compounds can be injection or compression molded, which eliminate the need for secondary operations and, thus, reduce costs.

Vibration Dampening

To reduce or eliminate these vibrations, engineers must either isolate or dampen resonant frequency. If isolation isn’t possible, engineers next introduce a damping material, which reduces, restricts, or prevents the oscillatory system’s energy. Ecomass achieves vibration dampening by selecting a practical and appropriate, high gravity soft base resin or Vibration damping material.

Ecomass’ high gravity thermoplastics composite materials have been utilized successfully in a wide variety of vibration dampening applications, including:

o aircraft audio headphones, to improve reception quality and minimize outside noise

o manual transmission shifters, where upper end sport/luxury automobiles drivers of appreciate the decrease in shifter rod vibration

o golf club weights, woods, irons and wedges, thus improving golfers’ swing and ball strike.

Ecomass Compounds meet the EU RoHS Directive, are lead free and nontoxic, completely satisfy international marketplace regulatory concerns, contain no toxic constituents or U.S. EPA hazardous materials, and comply with the Dodd-Frank Act, Section 1502.

Contact Ecomass today to check its case studies and products page to learn how it can deliver a custom tailored material for you.

0 comments:

Post a Comment