The surge in pharmaceuticals, reduced sales prices, and the rise in storing frequently used goods (disinfectants, health and beauty products, etc.) in large scale containers, has led to an increase in the manufacture of blow molded plastic bottles.

The blow molding technique utilizes a multi-layer technology to shape different types of plastic, including PET (polyethylene terephthalate), PE (polyethylene) and HDPE (High Density Polyethylene), into lightweight bottles, jugs, and jars. The method improves product stability, compatibility, and regulates moisture barrier requirements. As well, the process involves low costs.

The various blow molding processes include stretch, extrusion, injection, and compound blow molding. Extrusion blow molding is the most common process. A hot tube holds the plastic material in the mold. The machine blows air from the top. The shape is then formed and immediately frozen.

The dairy, food, auto, and beverage industries also use blow molded containers.

Ecomass Technologies

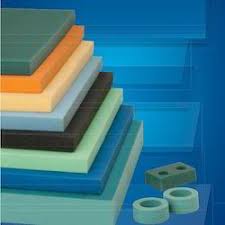

Since 1998, Ecomass Technologies has produced innovative solutions through thermoplastic composite materials, high density polymers, and high density plastics. It specializes in high density and lead replacement applications, which can be utilized in a wide array of applications, including vibration dampening, Radiation shielding, gamma ray shielding, and x-ray shielding.

Ecomass Technologies is primarily a material compounder dedicated to developing, devising, and creating the finest composite materials to empower its customers to produce the best possible parts. It also, however, helps its customers manage the injection molding process of products made with its materials (for example, blow molded plastic bottles and containers).

Ecomass Compounds satisfy the international regulatory concerns of the international marketplace, are completely nontoxic, and meet the EU RoHS Directives

Ecomass’ customer service team is recognized for its skill and responsiveness. See its website for contact information and its RFQ Form. It’s probably already worked on the solution you’re seeking.

0 comments:

Post a Comment