The thermoplastic composite industry is developing and new materials are being acquainted with the market. Choice of the correct material for your application isn't clear because of the absence of near information, as estimated by a free specialist, between the diverse material frameworks. Dependable material property information is significant amid the segment configuration stage. Information on preparing is expected to assess part manufacturability, while mechanical test information is required to foresee segment execution.

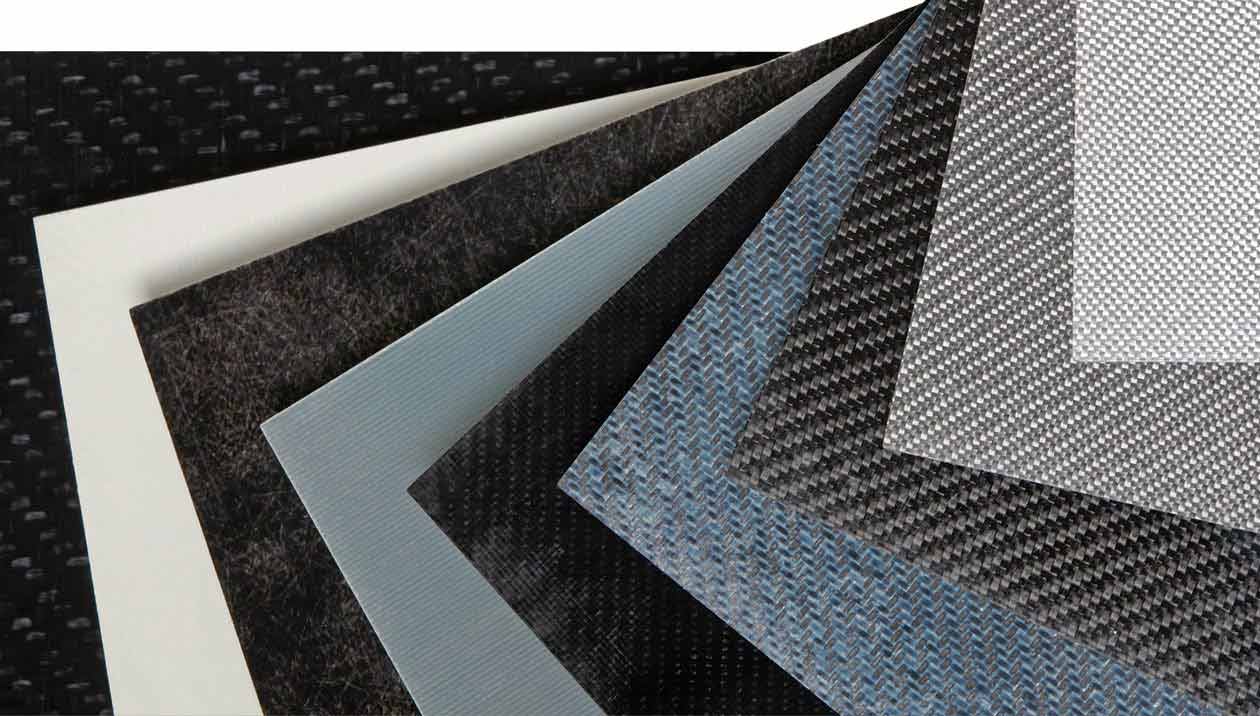

Engineered thermoplastics materials, as created by the individuals from TPRC and as showing up on the worldwide market, are evaluated for their execution and processability. The significant universal gauges for composite materials testing perform portrayal of mechanical properties, while the material's entire (thermo-mechanical) process history is painstakingly considered.

The rundown of advantages of TPCs absolutely presents a convincing defense for their thought as a material substitution in both metallic and thermoset composite parts and gatherings. Monstrous handling speed picks up versus thermoset composites, in addition to recyclability and strength make an exceptionally solid contention for engineers.

Regularly, a mechanical screening program incorporates estimation of elastic, twisting and compressive properties, and additionally interlaminar break strength esteems. In-house created test techniques and set-ups are utilized to describe the processability of consistent fiber strengthened thermoplastic composites.

A run of the mill test program to portray the formability, for instance, incorporates estimation of the shear and twisting inflexibility and additionally apparatus utilize and employ handle rubbing of the material at preparing conditions. The got material property information can be utilized for prescient shaping reproductions, utilizing committed programming, for example, Aniform.

Thermoplastic composite material are in a perfect world used to create composite segments in forms with short process durations. Keeping in mind the end goal to completely use this execution potential our tapes and sheets can be additionally handled with robotized tape laying machines or thermoforming forms joined with back infusion shaping.

The fire resistant material is solid in firmness, affect quality and dimensional solidness. Nonstop fiber-fortified thermoplastic composites are additionally uninhibitedly formable, simple to process and recyclable.

Also, these new material give incredible surfaces, taking into account a wide range of coatings and artistic creations. For the IT business, where the pattern is for littler, lighter, top notch items, polycarbonate composites are perfect for premium and thin lodgings. Equipment produced using polycarbonate composites have the look and feel of metal, however are essentially lighter. Indeed, constant fiber-fortified thermoplastic composites can lessen weight by 50 percent contrasted and aluminum. The lightweight characteristic is additionally applicable for the car business as polycarbonate composites are able to do altogether lessening weight and making vehicles more effective when utilized in entryway boards, body boards and seat backs.

0 comments:

Post a Comment