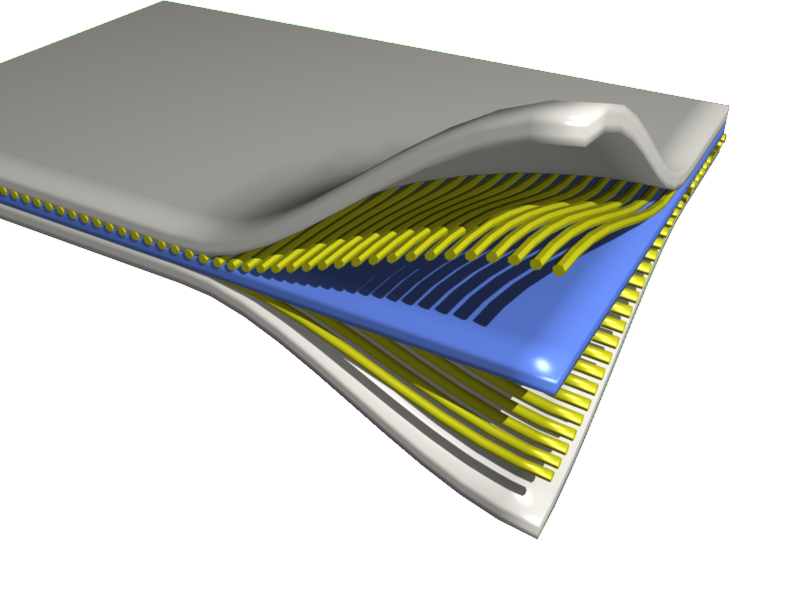

Injection molding is the go-to for thermoplastic composite materials because it is simpler, faster and easier. However, injection molding isn’t the only way to go about composite plastics. These polymers can also be produced with the help of pre-impregnated layups, a resin system which already has a curing agent, and is able to lay into a particular mold, without depending on additional resin.

Injection molding certainly has its specialization. After all, it offers high-volume molding, it is cheaper than its counterpart and also has lower mechanical properties. On the other hand, pre-impregnated layups are incredibly expensive to make, but the composite polymers are far stronger. The process is incredibly labor intensive as well, thereby limiting its application.

Thus came about a need for a third process, a material that helped to bridge the gap between these two technologies and allow for high-volume injection molding without having to compromise on the strength that pre-impregnated layup thermoplastic composite materials tend to offer.

It is easy to say that high-density plastics are suitable replacements for metals, but the strength offered by a moldable plastic is far lesser than that of a metal. As a result, the geometry concepts used for part design need to be re-engineered so that they utilize plastic materials. To do so, one must add more volume of plastics to the material, thereby having to compromise on the cost as well as the weight. Defeats the entire purpose, doesn’t it?

This is where new material technologies made all the difference. Today, it is possible to create high-density materials that offer mechanical properties which can not only meet, but also exceed the strength offered by metals without making you compromise on weight. As a result, it becomes easier to replace metal designs and reduce the volume of materials used while using plastic materials in a more efficient injection molding production process.

Thermoplastic Composites in Our Everyday Lives

Original equipment manufacturers from the aerospace industry have been depending on injection molded thermoplastic composite screws which are as strong as a metal. The need of the hour was to replace traditional titanium fasteners with plastic fasteners so as to enjoy weight savings. However, until now, thermoplastic polymers failed to deliver the desired mechanical performance or were simply not economical.

New and emerging technologies allowed thermoplastic composite materialmanufacturers to design plastic bolts which managed to meet the desired strength without sending budgetsthrough the roof. Perhaps the biggest difference that these bolts brought about was that they managed to reduce the weight by as much as 60% when compared to titanium bolts.

The Future

Today it is entirely possible to substitute metals with high-density plasticsto enjoy cost and weight savings. Despite being in the market for decades, heavy plastics were considered to be a niche product, but as the world wakes up to the benefits of substituting metals, these high-density materials are expected to onlyincrease in demand and in use.

0 comments:

Post a Comment