Injection molding and the products thereof has

already infiltrated nearly every aspect of your everyday life. You’re

likely to see dozens of injection molded parts all around you, in your

car, at work, in your house, even in your wallet. Considered to be one

of the most versatile methods of production, injection molding is not

only simpler and more efficient than many other production technologies,

it is also more reliable.

INJECTION MOLDING ADVANTAGES

Use Different Types of Plastic Simultaneously

One of the biggest advantages of injection molding is the ability to be able to use various types of heavy plastics

for the same manufacturing process. Co-injection molding makes it

possible to combine high density plastics to get the desired properties

and reduce issues associated with specific plastics.

Faster Production

Faster Production

The cycle time usually varies between 15 and 30, making it possible to produce a large number of parts per hour.

Colour and Material Flexibility

Injection molding makes it possible to change the color of the engineered materials without causing too many problems.

Higher Efficiency

Injection

molds can be customized to meet exact pre-programed specifications to

make the actual manufacturing process faster. The high production output

and increased efficiency also makes the manufacturing process cost

effective.

Flexibility in Design

Parts

made using the injection molding process are extremely flexible. Since

the molds are subjected to high amounts of pressure, high density plastics

get pressed harder when compared to other molding processes. As a

result, it is possible to add all kinds of details in part design.

Moreover, due to the higher pressure, complex shapes can be easily

designed and manufactured.

Enhanced Strength

It

is possible to add fillers to your injection molds. These fillers

reduce plastic density while allowing for increased strength after

molding. Plastic injection is perfect for parts that need to be strong

as well as durable, and this an advantage that is unique to the

injection molding process.

Expensive Initial Tooling

Getting

a tool is a costly affair. And even if you plan to make it yourself,

you need to have the right skills and an injection molding machine, both

of which are expensive as well.

Difficult to Estimate Actual Costs

Injection

molding comes with a number of uncertainties and this has the tendency

to throw your budget for a toss. It always makes sense to account for

unforeseen expenses when using this manufacturing method.

Restrictions in Part Design

Despite

all its versatility, injection molding tends to place certain

restrictions on part design. The main thing to understand is that an

injection molding tool is made from two halves which need to be pulled

apart so that the part can be released from the tool. Therefore, you

need to make sure that your parts are perpendicular to the tool opening

and ensure that the maximum part thickness for any particular spot is

less than 2mm – 3mm.

THE BOTTOM LINE

Injection

molding helps to make your production process as easy and hassle-free

as possible. Most parts that are ejected from injection molding have a

finished appearance, and the scrap generated from this process is

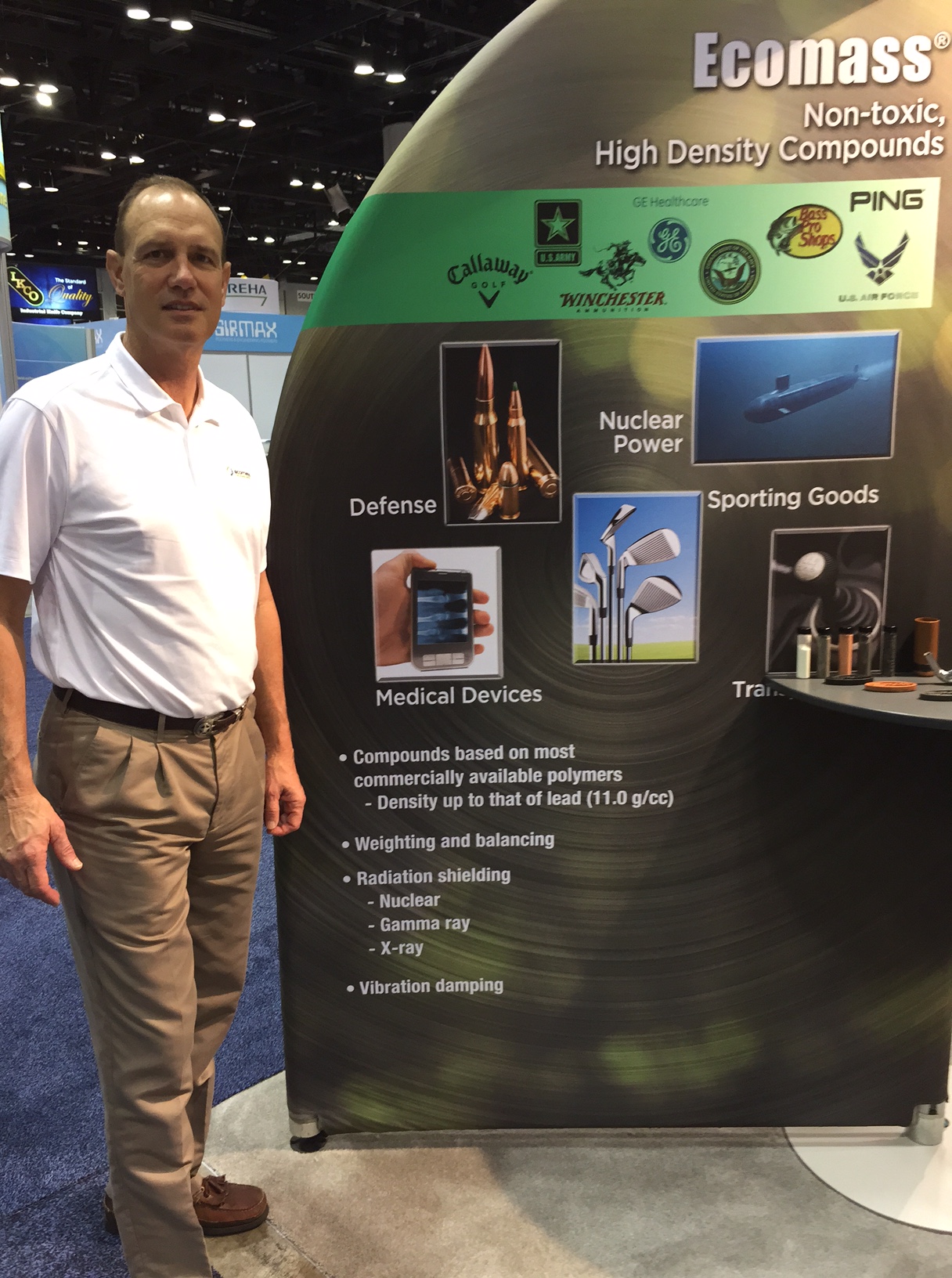

environment-friendly and can also be re-used. Ecomass Compounds presents top-of-the-line high gravity compounds that are tailor-made to your requirements

and specifications to help you seamlessly replace metals or simply make

your manufacturing process easier and cheaper than before.

0 comments:

Post a Comment