The search for better quality and durable material for different applications motivates manufacturers to try out different types of new materials. Thermoplastic is one such material that is considered to be durable, high in density and cost-effective. There are wide varieties of applications where manufacturers have managed to replace expensive materials with a thermoplastic material.

Today, this material is commonly used as the best replacement for lead within the ammunition industry. Apart from this, the material is also considered as green ammo as its use in ammunition industry reduces pollution.

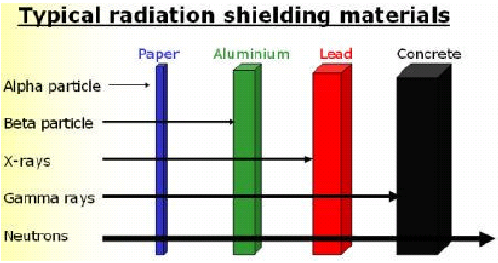

Thermoplastic material is also widely used in manufacturing machine components and for manufacturing x-ray shielding materials and machines.

The material is considered to be eco-friendly, safe to use and durable. So the moment thermoplastic material is being used, you can completely eliminate the use of metal.

General properties of thermoplastics

The main property of this material is that it can be made high-density material easily following simple processing methods. The material can also be molded into any shape or design using advanced injection methods. The material is also cheaper as compared to lead or other metals.

The process of molding and processing this material is also simple and does not involve using complex methods.

So, in simple terms, this material is considered as non-toxic by nature and property and is also easily sustainable. It can easily be recycled using simple methods. This is what makes the highdensity polymer more in demand today.

Why thermoplastic materials are more preferred industrially today?

There certainly are a number of reasons why more manufacturers prefer using thermoplastic materials for manufacturing other products. The best advantage is that thermoplastic materials can easily be made into materials with high specific gravity as compared to other metals.

The moment proper filler material is added to this, its specific gravity and mass can be increased. Even if the mass and a specific gravity of this material changes, still its cost remains much lower as compared to lead metal.

Another major advantage of using thermoplastic material is that it offers with no design restriction features and practically be cast into any design. You can also make use of complex methods for redesigning this material into any design or shape. This material can be used as green ammo for making lead free ammunition and projectiles.

Special properties

Thermoplastic materials are considered as special materials that have specific properties. These are non-toxic in nature and so can be used within the medical field as x-ray shielding materials. The material can also be sustained easily and offer with tensile strength.

Due to these properties, the material is also considered safe to use the material in most areas within the manufacturing unit.

Uses as a replacement for lead-based ammo

As termed earlier, the material can be considered as non-toxic ammo and is ideal for replacing lead caps. This offers a safe way to be used within wildlife hunting games. Apart from this, high density polymer is widely used in the ammunition industry and game reserves for practicing shooting games.

When using this material, you may not have to worry about lead poisoning which can also be a leading cause for damaging your brain cells.

0 comments:

Post a Comment