In the civil engineering field, there is more demand for thermoplastic composite materials; basically, it is a new material in the construction field. The ultimate fact is that the use of proper thermoplastic composites is leading to offers some admirable benefits compared to thermoset materials.

In the past 20 years there is huge investment occurred in the engineering and construction arena and the introduction of thermoplastic composite materials is one the most favorable result of it. There are very few top-rated manufacturing companies are involved in the proper production of such materials.

Why pick thermoplastic composite:

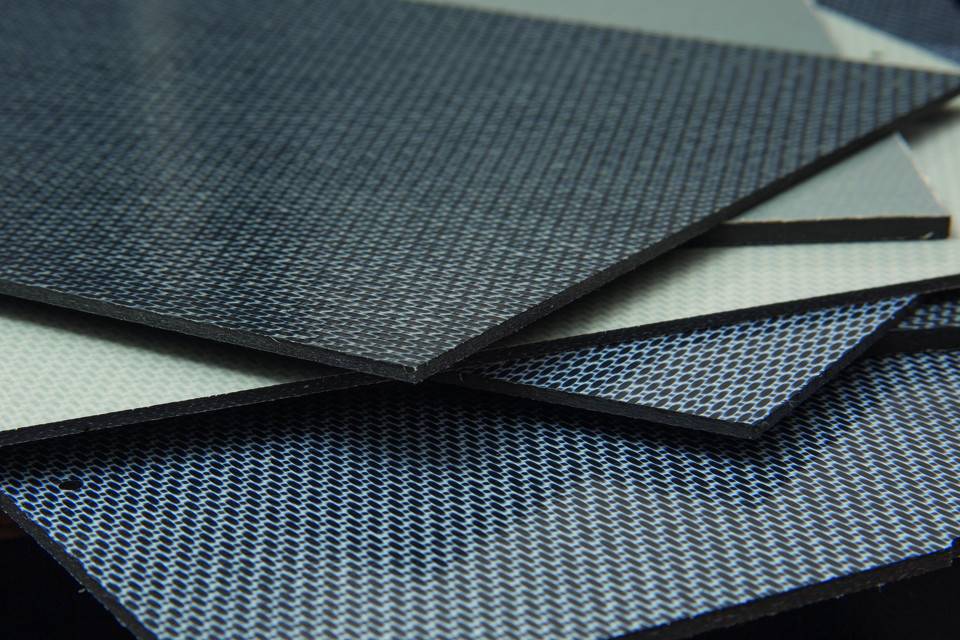

In the current time, many people are well considering the best use of modern thermoplastic materials like polythene, nylon, and polypropylene, etc they are very tough materials and can be easily able to melt it again effectively.

Another more convincing fact related to a thermoplastic that attracts the customer to pick the modern materials in the engineering field is all due to their attractive features. Some of the dominated advantages are making them more preferable materials compared to any conventional composites like resin, epoxy or polyester.

Some of the top admirable features are like:

• They are very tough materials that make them a great source of robustness

• The fiber volume can differ across each section

• It is more convenient in improving environment tolerance

• The raw materials which require in this are cheaper

• They are eco-friendly materials for modern society

• Easy to melt them again

All these listed benefits that are associated with thermoplastic composite materials are making them increasingly valuable products in the market. Many manufacturing units and other construction sectors are more reliable in using such reasonable materials that are very useful.

The real assets are recycled features for thermoplastic materials:

One of the most admirable benefits of applying modern thermoplastic materials is the ability to recycle them effectively after use. The use of advanced high density plastic contains materials that are leading a great source of a lighter, less fuel-intensive and better alternative option for thermoset composites.

The materials which can get recycle again after use have great benefits for society and the environment too. Whereas the thermoset was not having the opportunity to get transferred again or recycled but the use of another cross mechanism materials which is called thermoplastics can be easily able to recycle.

The drawback with the uses of traditional thermoset materials was the features of one time uses. The materials were having the characteristic of hardening permanently at once. At presently thanks to the alternative option that has been developed the availability of high density plastic or the presence of thermoplastics materials which are having good assets to recycle them again.

Another advantage of the application of thermoplastic is that they are very soft by nature when the composite parts are heated. This feature allows the materials to get the desired shape or can easily able to weld them accordingly. When the melting becomes very easy and safe for the materials then it can be easily able to access them or recycle them efficiently.

0 comments:

Post a Comment