In February 2018, Engineering.com reported that an ultra high molecular weight polyethylene, a low friction plastics, mimics ice’s characteristics, or produces an “ice effect,” when lubricated.

Such polymers have already been used on the bottoms layers of racing skis, but not on the top of a track. Researchers at Harvard recently revealed the polymer’s “ice effect” value for Olympic sports such as bobsledding for countries that don’t experience cold conditions or snow. Now, such countries can closely duplicate the friction ice creates on the bottom of a bobsled, luge, skeleton, etc. And, there’s no risk of damage as the spray is self-healing. Early testing on plastic tracks showed the same speeds as on ice tracks.

Providing other countries the opportunity enjoy sledding sports others and letting more people compete in sledding competitions is, of course, one huge advantage. Other advantages include reducing environmental impact and cost savings. Low friction sled costs equal are around $4-$5, while standard sledding costs exceed over $90 million.

Researchers hope to utilize the “ice effect” to the 2020 Youth Olympic Games in Switzerland.

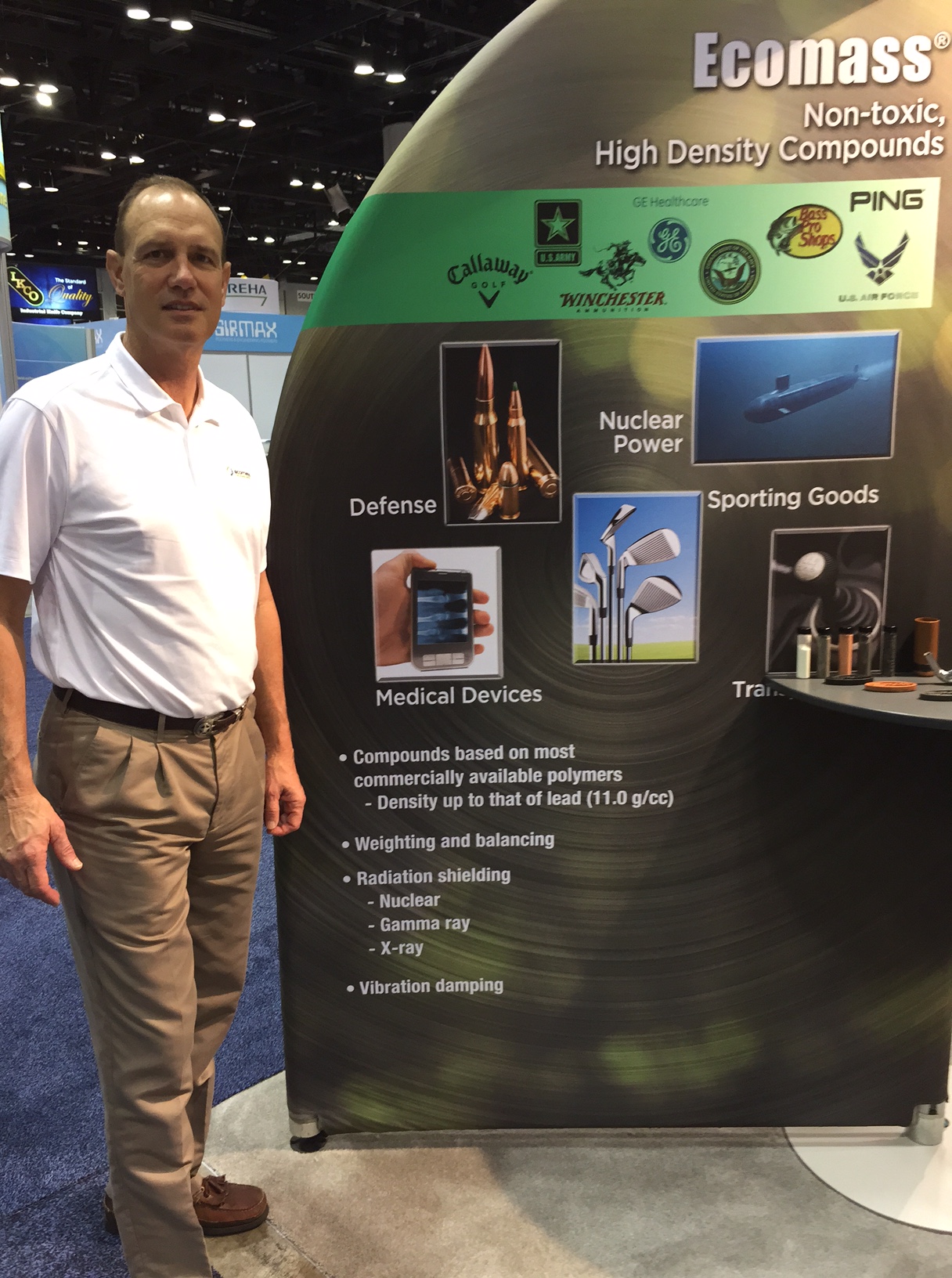

Ecomass Technologies

Since 1998, Ecomass Technologies has offered cutting-edge solutions through advanced composite materials, engineered thermoplastic composite materials, high density plastics, high density polymers, and gamma ray shielding. Its skill and expertise allows customer to focus on form and function while it resolves the products’ material challenges. It strives to provide customers with the highest performing, lowest priced materials so that they can effectively compete in their markets.

Ecomass’ high gravity compounds are engineered to replace traditional materials and have been used as a substitute for lead, aluminum, steel, stainless steel, brass, bronze, copper, and other metals in the following applications:

o To replace lead projectiles with nontoxic frangible projectiles as training ammunition for military and law enforcement personnel.

o To shield -ray and gamma ray sources in medical and industrial devices.

o As a Vibration damping material in the automotive and sporting goods industries.

o To balance weights and reduce the loads to which a part is exposed, thereby increasing its service life.

These are really just a few examples of what Ecomass industries’ compounds can do. It can let people who in areas that never see snow actually enjoy bobsledding.

All Ecomass Compounds meet the EU RoHS Directive, are 100% lead free, do not contain any U.S. EPA toxic or hazardous materials, and comply with Section 1502 of the Dodd-Frank Act.

See Ecomass’ website to learn more about its compounds, products, and services and/or fill out its RFQ form to learn how it can develop and deliver a solution to satisfy your needs.

0 comments:

Post a Comment