Heat shield Products has developed products that block out annoying sounds and vibrations without adding weight. They utilize thermal barriers that employ acoustic and Vibration damping materials.

A stick-on sound insulation is twenty percent lighter than other acoustic damping sheets. It provides almost twice the sound-insulation ability, is only ½ inch thick, and weighs just 0.39 pound per square foot. It can be placed in extremely constricted area, underneath upholstery without issue, and it takes little effort to remove and reattach them. It’s effective on any aluminum, steel, finished fiberglass, or plastic surface and lessens structural resonance to create a snugger, softer, and more comfortable ride.

Another product is a lightweight, fluid sound coating that one can spray, roil, or brush onto a clean and prepared surface, such as a speaker box or mounting area. It also acoustically dampens fiberglass and plastic enclosures.

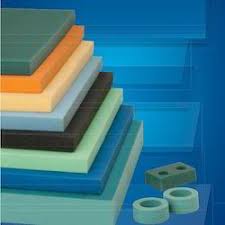

Yet another product is closed-cell urethane foam that works as a buffer between to components to reduce squeaks, rattles and buzzes, including those from connection rods in door handles and locking mechanisms. On speakers, it results in a crisper, cleaner sound. It can also be outsides.

Ecomass Technologies

Ecomass Technologies is the pioneer and technological groundbreaker in high density plastics, high density polymers, thermoplastic composite materials, and high density engineered thermoplastics. Its sales and engineering teams have helped commercial and government customers conquer physical property challenges by developing over 100 high gravity thermoplastic composite materials engineered for weighting, balancing, radiation shielding, and vibration dampening applications.

All materials have natural or resonance frequency. Energy waves, which have both frequency and amplitude, cause vibrations. When technicians and engineers can’t isolate and reduce energy at the source, they utilize dampening materials to reduces, restrict, or prevent oscillations and, thus, reduce energy.

Aircraft audio systems, sports and luxury automobiles industrialists, are just of the few who have successfully used Ecomass’s Vibration dampening compounds to achieve their developmental goals.

All Ecomass Compounds meet the EU RoHS Directive, are 100% lead free, do not contain any U.S. EPA toxic or hazardous materials, and comply with Section 1502 of the Dodd-Frank Act.

Contact Ecomass today or see its website and complete one if its RFQ Forms to find out how you and/or your company might be able to use its compounds for vibration dampening or apply them to any other valuable use.

0 comments:

Post a Comment